Most people have never heard of a Luminary candle before or they assume it is something similar to a traditional wick burning candle. I thought I would clarify exactly what they are and share a bit more about the process of making these beautiful nature themed candles.

What is a Luminary/Hurricane Candle?

This style candle can been referred to as a Hurricane, Luminary or Everlasting candle. The simplest explanation is that it is a re-usable hollow wax shell, similar to a lantern or vase shape, made from a translucent and very high melt point wax that can withstand the heat of a burning tea-light inside of its base without melting. Flowers, leaves, fruit, photos, etc. are embedded within the wax shell, a lit tea-light is placed inside the base of the candle, lighting up and illuminating the embedded objects, giving off a lovely warm and glowing backlit effect. When used properly, it will last forever, the outer wax shell will never melt away. The embedded items are completely encased in wax on the inside and have enough distance from the tea lights flame, so there is no risk of the embedded items becoming flammable. They also look just as beautiful unlit. Most can even be filled with water instead and used as a vase.

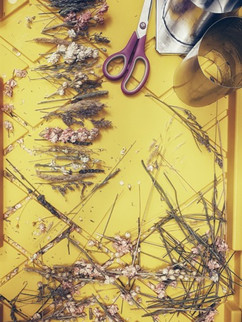

I love to use locally foraged plants in my candles. I anxiously await the arrival of spring each year for the wildflowers and ferns to start budding and blooming. Closer to summer, local farms open up their fields of flowers to the public to come and harvest their own bundles by hand. This is where I get my Larkspur and Lavender. Everything else is foraged from the wild. Summer is my favorite time to harvest most of the plants I use. There are never ending fields and meadows of all sorts of varieties of wild grasses, queen annes lace, salsify, sheep sorrel and more. Towards the end of summer and into the fall, more things start to dry out and go to seed. I love the array of textures to be found in the fall! Dried plants this time of year have a very muted/vintage appearance and look so good preserved in wax. I either traditionally press or preserve in silica many of my plants. But sometimes the best way to preserve them is to just hang them upside down to naturally dry out on their own. My workspace is surrounded by hanging bouquets and shelves filled with all of my foraged finds from the year. It makes me feel like I am working in a meadow! And it makes working through the gray rainy winter season here much more bearable.

Almost any item can be preserved within the wax shell, as long as it is free of any moisture and less than 1/2" thick. Seashells, small pine cones, acorns, cinnamon sticks, even dried fruits work well. I can even embed paper and photographs! Many years ago, this was my main focus. I would make personalized luminaries for weddings and memorials, using a clients photo, a wedding invitation or most times I would design from scratch a custom layout with text and photos that was then printed onto translucent paper and embedded. I will be offering these options again closer to the holiday season this year!

The Process of Making a Luminary Candle

All of my candles are hand-poured by myself in my home studio. I work with two different types of 160 degree + melt point paraffin waxes. Unfortunately, natural waxes would be unable to withstand the temps, hold their shape and are too opaque to allow embedded items to be seen. However, since this wax shell will not be what's burned, I am comfortable using it. I do not add any dyes, chemical additives or fragrance oils to any of my wax, to keep things as allergen friendly for myself and everyone else. My tea light candles are made with 100% palm wax and natural cotton wicks. They are the cleanest burning option for those concerned about the air they breathe. Though you can choose to burn any type of tea-light you like, including scented tea-lights.

There are many techniques and tools that go into creating a candle. Most I have fine tuned myself over the years to suit the specific look I want to achieve and the space I work in. I have my molds custom made to size out of tin from a local welding company. I make the rest of the components myself out of aluminum flashing and steel and other random things. 20 years ago, it wasn't too hard to find the tools needed to make these. This art form has quickly disappeared and nowadays, very few people in the world make these anymore. So it is nearly impossible to find anything ready made, so I must get creative with how I make my tools for myself.

This isn't a clean and orderly craft in anyway. Working with liquid wax in temps exceeding 200 degrees, while having to transport it within a mold multiple times, can be a bit of a mess. I have burned myself and ruined more carpets and tabletops in my years than I care to admit. But the results are definitely worth the effort to me. I can typically produce 8-12 candles in a full work day. The need to melt out and clean a mold of any wax residue left behind after each use is the most time consuming and annoying part of it all. It also takes some time to melt up to 3 lbs of wax for each candle to be made. I work on a small scale and my wax melter can only handle so much at a time. I wont go into detail on all of the steps, as they probably wouldn't make much sense to a non candle-maker. I take lots of extra steps to ensure things stay in place, are bubble free and the surface retains a shine. And then once the candle is cooled and de-molded, a whole new set of time consuming steps take place to finish it off. Maybe that is why nobody makes these anymore :) But I don't mind the time it takes. I love the slow process of making these and will never stop.

There are two different finishes to the candles surface that I make. Some have a shiny smooth surface and others, I partially melt away the outer surface to expose more of the embedded material. I currently do not ship my candles in the hot summer season, when temps in vehicles during transport can sometimes exceed 140 degrees. The candle would not melt at all in these temps but the wax could get soft enough in spots to leave indentations or surface imperfections from the packaging it is in. They are very delicate to ship and require a lot of padding/packaging.

I hope all of this gives everyone a better understanding of what a luminary candle is!